AGen in Production

Scan Print Peel Stick make easy with AGen

In today's fast-paced world, efficiency and accuracy are crucial in every industry. The packaging industry is no exception, with businesses looking for ways to streamline their processes and reduce errors. One such process is the reproduction of labels on carton boxes, which involves scanning, printing, peeling, and sticking the label on the carton box. AGen will explore the steps involved in this process and how AGen software has made it easier and more efficient.

Step 1: Scanning

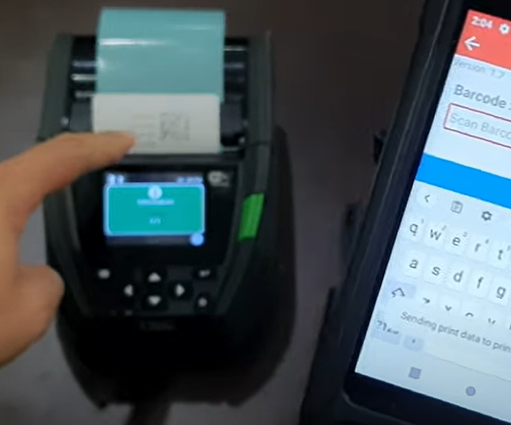

The first step in the reproduction of labels on carton boxes is scanning the original label. This is typically done using a barcode scanner or a mobile computer that can read the information on the label. The scanner captures the data, sends it to printer, and sends it to a backend AGen server computer system that stores the information for later use.

Step 2: Printing

Once the original label has been scanned, the next step is to print a new label. This is done using a specialized printer that can produce high-quality labels quickly and efficiently. The printer uses the information captured during the scanning process to produce an exact replica of the original label. The printer may also be programmed to produce labels in varied sizes, colors, and formats, depending on the needs of the business. In AGen, the scanning and printing process is fully integrated.

Step 3: Peeling

Based on traditional batch printing and labeling process. Once the new label has been printed, it needs to be peeled off from its backing. Before this process, the label will be collected and rewind into big roll form. After that this sticker will be loaded into a big peeler machine. The peeling process is typically done using a machine that can automatically peel and dispense labels. The machine uses a special adhesive that allows the label to be easily peeled off and applied to the carton box. However, in AGen solution, this process will also be integrated into scanning and printing processes. AGen will make sure the scan print and peel are done in single step and the label is waiting to be stick onto the carton box.

Step 4: Sticking

The last step in the reproduction of labels on carton boxes is sticking the new label onto the box. The user who does the scanning just needs to lightly pick up the printed label, stick the label with the box, and apply it with just the right amount of pressure, ensuring that the label adheres properly and does not come off during shipping or handling.

AGen software has played a significant role in making this process more efficient and accurate. Automated systems have replaced manual processes, reduced the risk of errors and increased productivity. Barcode scanners and specialized printers can capture and reproduce information quickly and accurately, while on demand peel and stick labels eliminate the need for additional steps in handling labels.

In conclusion, the reproduction of labels on carton boxes is a crucial process in the packaging industry. It requires accuracy, efficiency, and attention to detail to ensure that the right labels are applied to the right boxes. With the help of AGen software, this process has become more streamlined, accurate, and efficient, allowing businesses to save time and money while maintaining a high level of quality.

User01

Username: user01

Password: user01

Username: user02

Password: user02

Username: user03

Password: user03

Learn How to download apk to your mobile device Learn now.